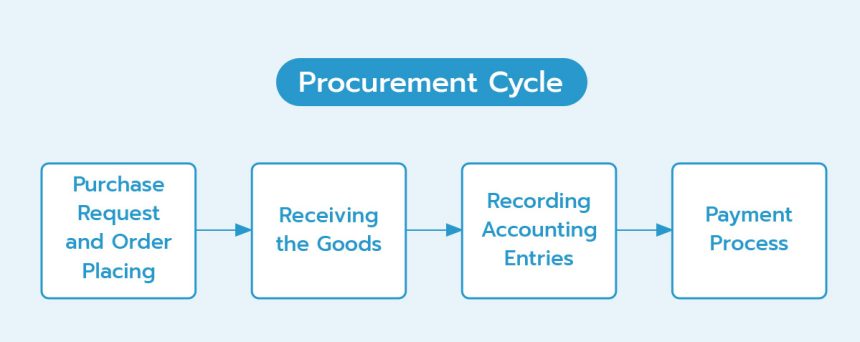

Each and every business relies on a steady flow of goods and services for maintaining its operations and meeting customer demands. The purchase order process is an essential first step that sets an entire procurement cycle in motion. This multi-stage process has certain steps like carefully identifying an organisation’s requirements, and vetting as well as selecting appropriate suppliers, negotiating terms, issuing formal purchase orders, overseeing order fulfilment, and ultimately receiving and inspecting the goods or services ordered. While seemingly straightforward, the purchase order process is a meticulously orchestrated sequence of events that ensure companies can acquire resources they need to function effectively and efficiently.

- The Need for Goods or Services

No matter how big or small, the operation of any firm depends on a consistent flow of products and services. It could be as simple as office supplies or as intricate as specialised industrial equipment. Without these vital elements, corporate operations would come to a complete stop, making it impossible for the company to provide for its clients or make money. The first and most important phase in the purchase order process is determining the requirement for particular products or services. It necessitates a thorough comprehension of the operations of the company, inventory levels, and upcoming demands.

It is imperative for businesses to consistently evaluate their needs, foreseeing shortfalls and making advance plans to guarantee an uninterrupted supply of resources. Production, sales, and operations are just a few of the divisions working together on this requirement assessment. Frontline staff members’ opinions, who deal with the products and services firsthand, are very helpful in identifying areas that need to be updated or replenished. The next step of the process for the business is to identify the ideal provider to meet the need after it has been clearly defined.

- Identifying the Right Supplier

Identifying the appropriate supplier constitutes a pivotal phase in the procurement process. Organisations can leverage their existing vendor relationships, which offer advantages such as familiarity, trust, and negotiating leverage. However, it is imperative to maintain an open mindset and proactively explore new suppliers who may offer more innovative, cost-effective, or superior quality solutions.

Numerous potential partners can be discovered through industry events, networking within professional circles, and online supplier directories. Peer or subject matter expert recommendations can also offer insightful information about a supplier’s standing, competencies, and history of providing outstanding customer service. Finding a supplier who is in line with the organisation’s long-term objectives, quality standards, and core values is the ultimate goal, in addition to meeting its current needs.

- Gathering Quotes and Negotiating Terms

Getting quotations and working out terms are important steps that lay the groundwork for a fruitful collaboration. Both sides must communicate in an honest and open manner and put out their cards. The supplier offers their capabilities, pricing structure, and suggested dates, while the firm describes its unique requirements, ideal quality standards, and financial limits. This back-and-forth conversation makes it possible to clarify, reach a compromise, and consider other options. In order to negotiate effectively and arrive at a solution that best satisfies all sides’ interests, one must strike a balance between assertiveness and flexibility.

- Placing the Purchase Order

The crucial step in transforming the discussions into a formal, legally-binding agreement is putting in the purchase order. There is no room for doubt or misinterpretation because this document acts as the blueprint for the entire transaction. Every aspect is covered in great detail, including product details and quantities, prices, delivery schedules, and terms of payment. Particular specifications are also spelled out in detail, such as customised configurations or packing guidelines. Before signing the purchase order and committing to the terms and conditions stated within, both parties must carefully read it to make sure everything is in line.

- Processing the Purchase Order

Their staff carefully goes over the paperwork, double-checking each detail to make sure they have the raw materials, inventory, and other resources needed to complete the order exactly as written. The following stages could entail manufacturing, assembling, packaging, or organising the necessary staff and schedules, depending on the type of goods or services. Every step of the process is subject to strict quality control procedures to ensure that the finished good or service satisfies the established requirements and standards.

- Receiving and Inspecting the Goods or Services

As the scheduled delivery date draws near, the company gets ready to accept the products or services. It’s time for a comprehensive check to make sure everything fits the parameters listed in the purchase order when the cargo arrives. Maintaining quality control and spotting any possible problems or inconsistencies depend heavily on this phase.

- Approving the Invoice and Making Payment

Following receipt and inspection of the products or services, the provider will send out an invoice for payment. After that, the company will examine the invoice, compare it to the initial purchase order, and authorise the payment if everything checks out. This action is essential to preserving positive working relationships with suppliers and guaranteeing future smooth delivery of goods and services.

- Record-Keeping and Inventory Management

The updating of the company’s records and inventory management systems is the last phase in the buy order procedure. This entails keeping a paper trail for a future reference or auditing needs, along with updating inventory levels as necessary, as well as entering a transaction into the accounting books.

- Continuous Improvement

Despite the apparent simplicity of the purchase order process, companies are constantly seeking methods to improve along with streamline it. This could entail discovering more effective inventory management strategies, negotiating better terms with suppliers, or putting digital solutions into place for quicker processing in addition to communication. The objective is to continuously enhance the procedure, cutting expenses, cutting down on delays, and raising overall effectiveness.

Conclusion

The purchase order process and tail spend analysis are meticulously planned that guarantees organisations can obtain the products as well as services they require to prosper, from the first need to the last record-keeping. Every stage is important, and when done right, the entire process functions.